Environmental sustainability of container terminals is challenged by the increasing goods transport that culminates in busier operations, which leads to considerable levels of greenhouse gas emissions and fuel consumption of cargo handling equipment. The PortForward project addresses this challenge by developing an innovative decision-making support system called the Green Yard Scheduler (GYS) with the primary objective of greening container terminal operations.

The Green Yard Scheduler is being developed by Brunel University London using the case of Vigo container terminal. The port authority of Vigo and the terminal operator, Termavi, provide scenarios and data. The detailed sustainability analysis of terminal operations is done by Leitat Technological Center based in Barcelona.

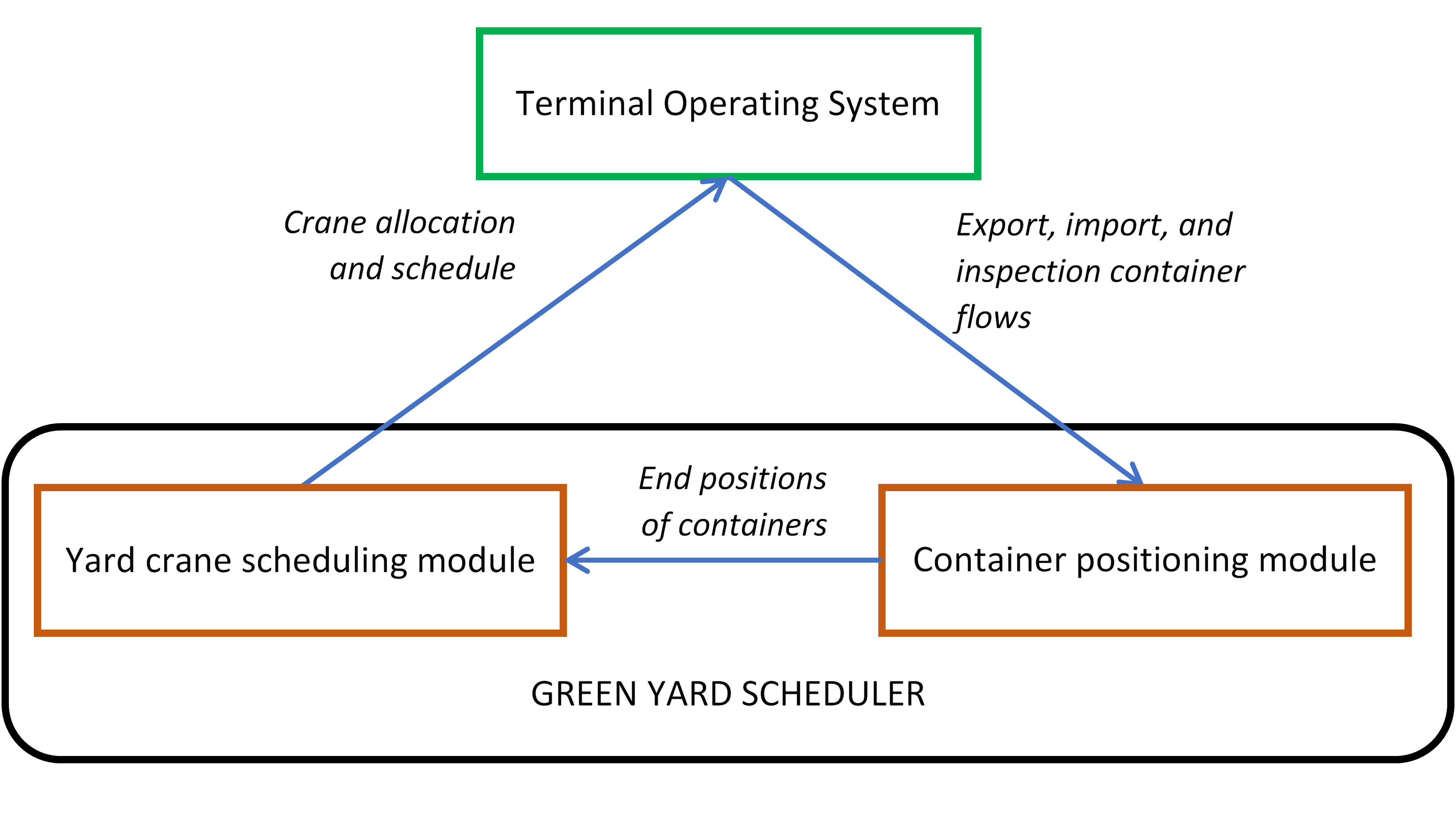

The container yard operations in Vigo terminal are optimized by two modules designed within the Green Yard Scheduler: The Container Positioning Module (CPM) and the Yard Crane Scheduling Module (YSM). These modules interact with the port’s Terminal Operating System (TOS) and assist the terminal operators with the efficient completion of the container movement requests in the yard, where CPM allocates storage positions to the incoming containers and YSM determines the schedule of the container handling equipment such as rubber-tyred gantry cranes and reach stackers. GYS aims to minimize the completion time of the requests and total energy consumption of the equipment, and thereby improve the operational efficiency of the entire terminal and reduce the environmental impact of the operations.

Information flow diagram of GYS:

Yard Crane images from Vigo terminal

Reach Stacker, Rubber-tyred gantry crane, View of the terminal from the sea, View of the terminal (© Termavi )