On 9 February 2021 Prof Afshin Mansouri, PI, Dr Cihan Butun and Dr Ran Wang, Research Fellows of the PortForward project team at Brunel University London, did a successful demonstration of the GYS (pre-beta version) to an audience of operational & technical managers from of Vigo Port Authority (A.P. Vigo) and Vigo container terminal operator (Termavi) in an online meeting (Figure 1).

Figure 1: GYS demonstration meeting with participants from Brunel University London, A.P. Vigo, and Termavi

The Green Yard Scheduler (GYS), an innovative decision support tool that is being developed by Brunel University London in the work package WP5 (Green Scheduling and Sustainability of Operations) of the PortForward project, optimizes container terminal operations by prioritizing environmental sustainability alongside terminal productivity in collaboration with the Vigo Port Authority, LEITAT Technological Center, and IMEC Research Center. Vigo container terminal (Figure 2) is the designated project use case of WP5, and serves as the main platform for the integration, and offline/online testing of the GYS.

Figure 2: Vigo container terminal

The meeting started with the presentation of key features of the GYS and the progress made so far in the GYS software development. Brunel team then shared the analysis insights of over three million container yard operations recorded at the Vigo container terminal between 2010 and 2018. The annual breakdowns of productive/unproductive container movements and distances travelled by internal & external movement vehicles were visualized to show the trends in the terminal productivity.

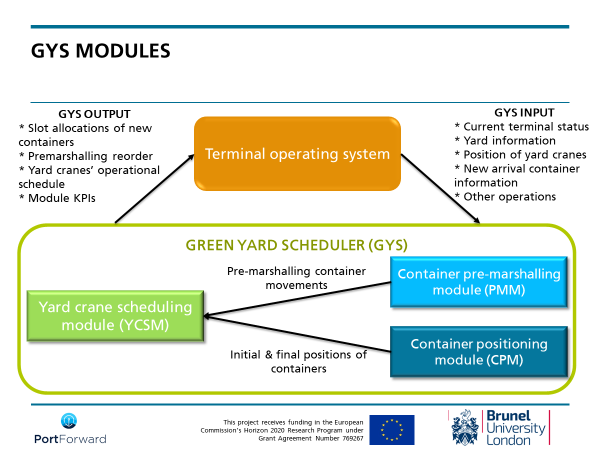

Figure 3: Architectural diagram of GYS

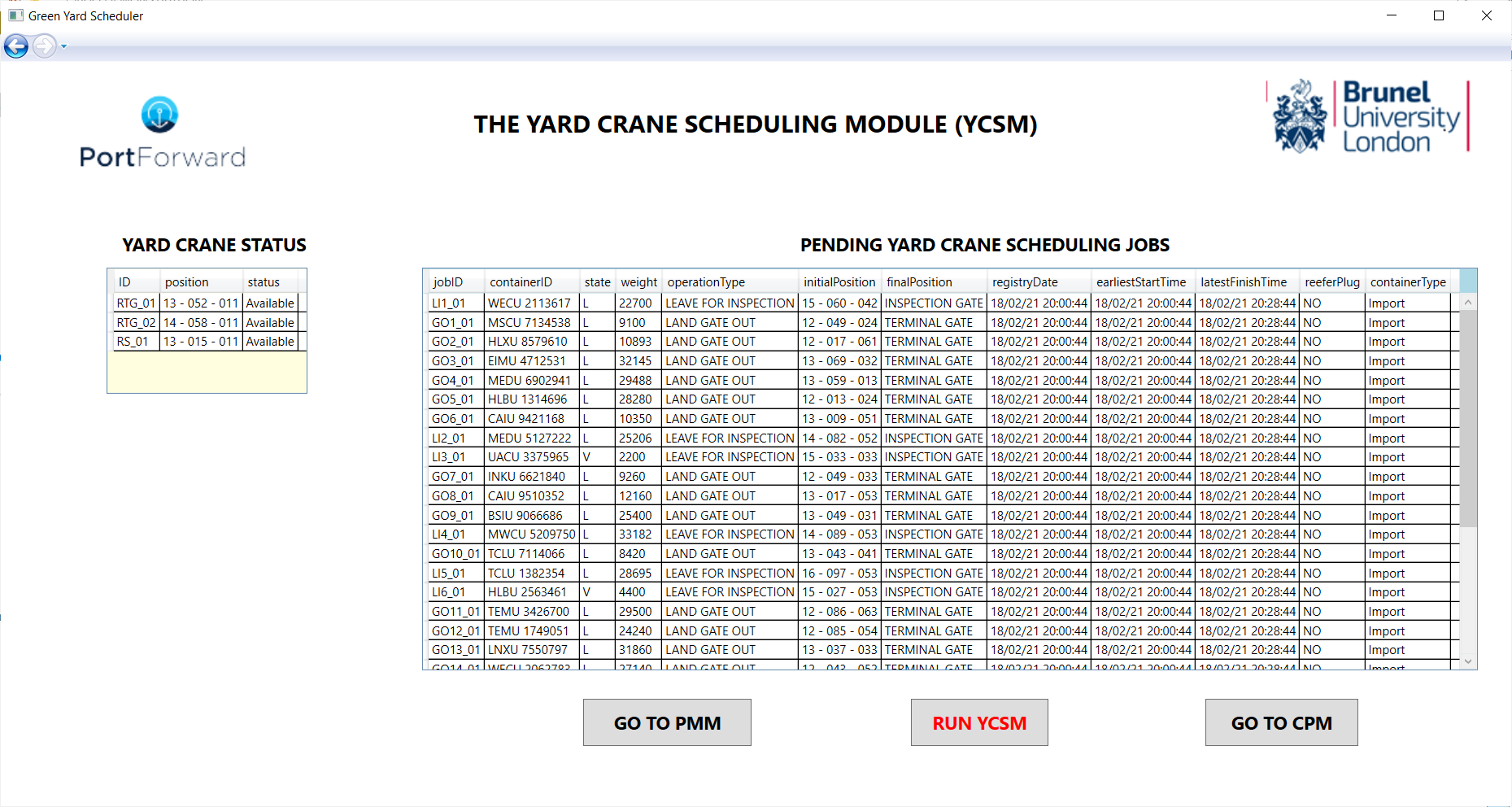

After a brief overview of the three optimization modules (container pre-marshalling (PMM), container positioning (CPM), and yard crane scheduling modules (YCSM), Figure 3), GYS was run with the following use case scenarios designed and generated by the Brunel team using historical terminal operation records provided by Termavi:

-

Positioning of new containers: First, CPM is run to allocate empty slots in the yard to 50 new containers, followed by YCSM to sequence and schedule the positioning jobs to available yard cranes.

-

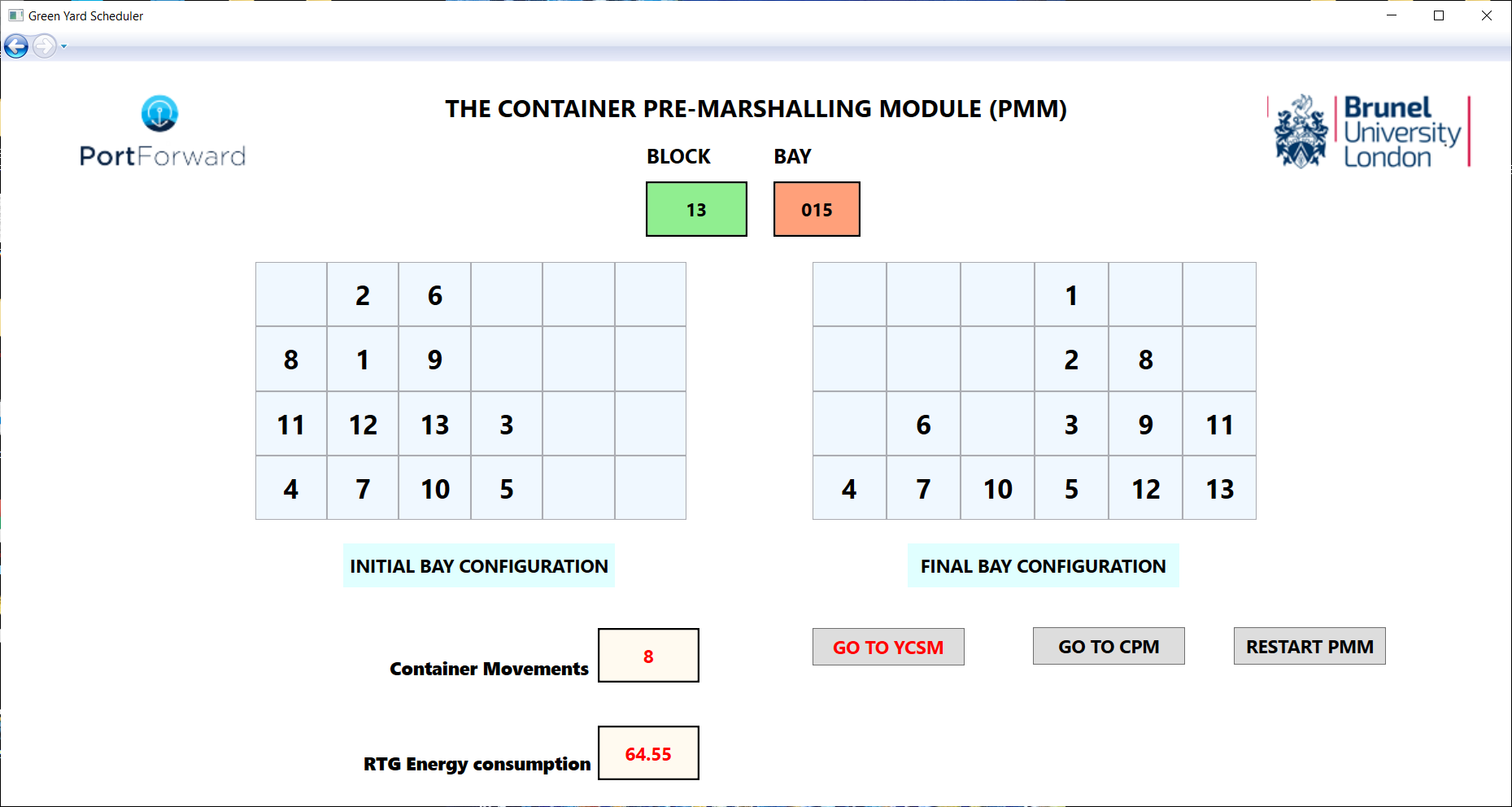

Pre-marshalling of a yard bay: PMM is used to obtain the reordering sequence of containers in a selected bay area of the yard. YCSM then allocates this sequence of movements to an available yard crane.

-

Scheduling of container operations: Removal of 30 containers from the yard for inspection or by the importer is sequenced and scheduled to available yard cranes by YCSM only.

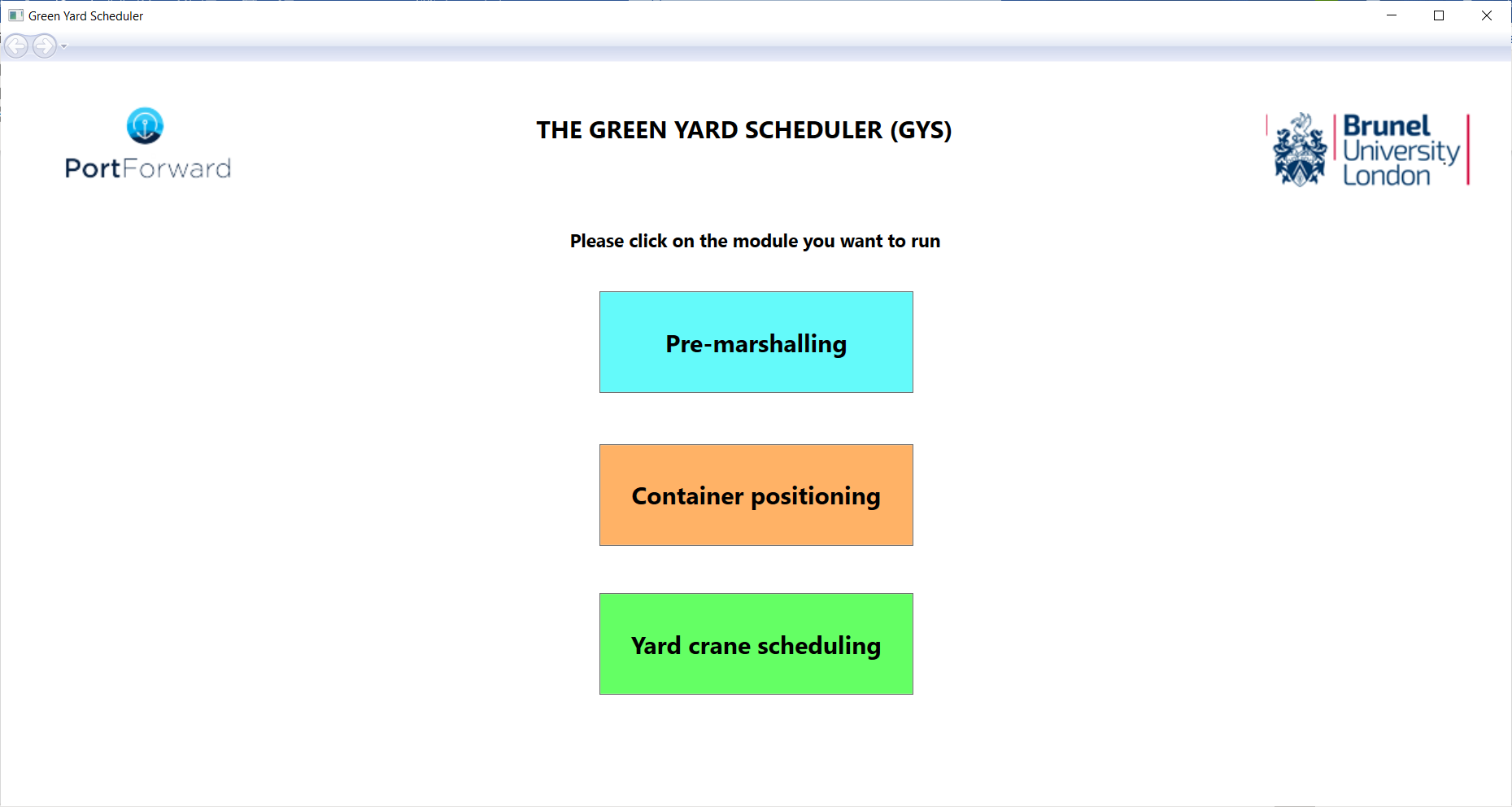

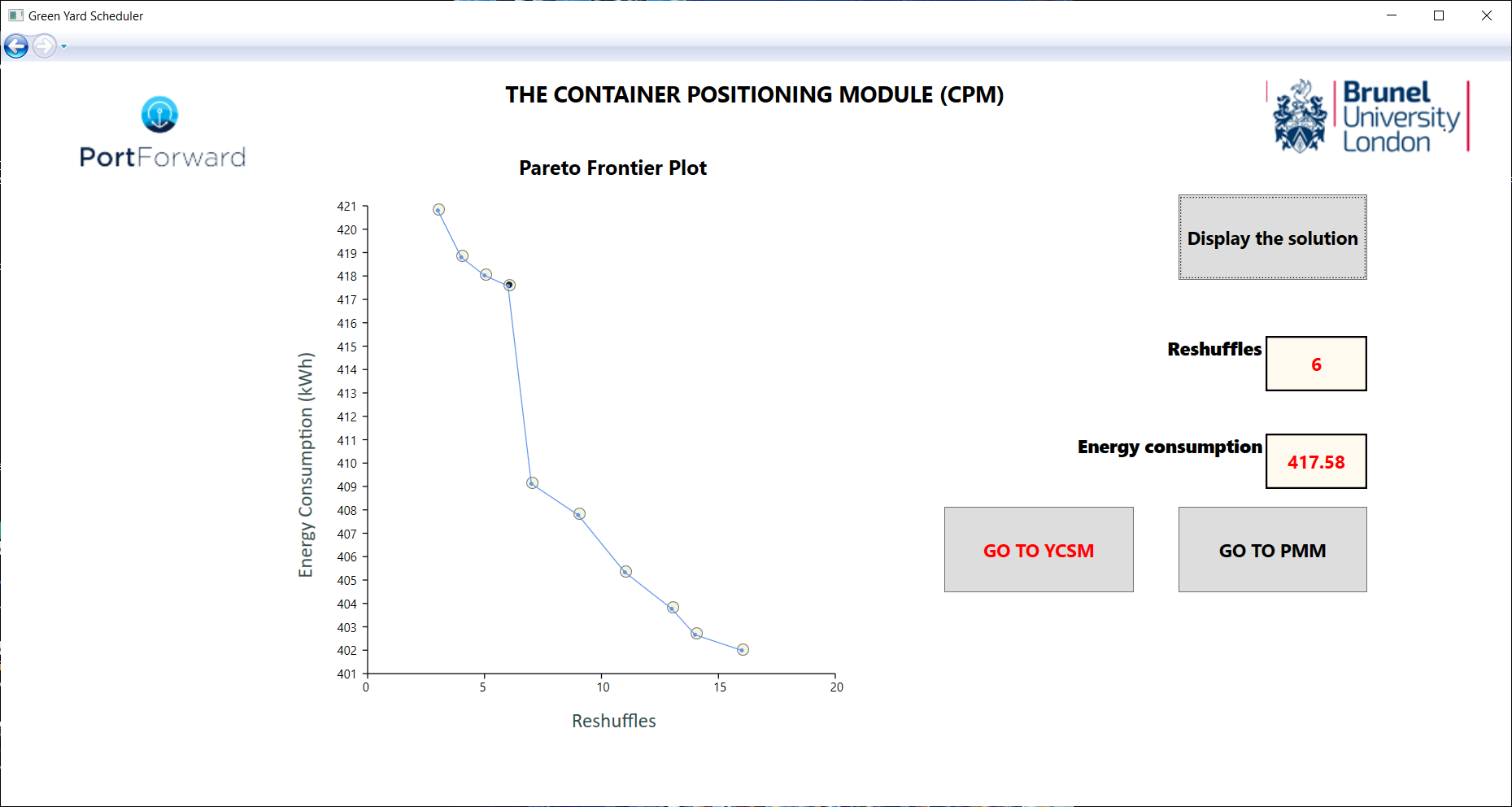

All use case scenarios were demonstrated with the graphical user interface of GYS, which has been designed and developed by considering notions such as user friendliness, visualization of module inputs & outputs, and smooth interaction of subsystems and processes (Figure 4). The optimization modules, which work seamlessly in the background, employ suitable heuristic solution procedures to 1) emphasize the potential trade-off between the KPIs of each module, 2) obtain a high quality and diverse set of solutions, and 3) achieve an enhanced performance in terms of computational time and efficiency. In the demonstration, mock databases in .csv file format were generated for each scenario to imitate the actual data exchange process between GYS and the Vigo container terminal operating system (TOS).

The overall reception of the GYS demonstration by the meeting participants was very good. The future user of the GYS tool, Vigo container terminal operator Termavi, expressed their positive opinion and provided Brunel team with constructive comments and feedback. The meeting has marked an important milestone manifesting the steady progress in the development of GYS despite the communication problems and travel restrictions caused by the COVID-19 pandemic.

Figure 4: GUI and optimization modules of GYS

Building on the mutual understanding reached in this meeting, Brunel team and other project partners will continue to work in close collaboration with Termavi and make the beta version of the GYS ready for testing and implementation in the Vigo container terminal. Upon the successful beta testing & implementation, measurement of work package KPIs, and evaluation of improvements observed in the terminal’s operational efficiency and environmental sustainability, GYS will be finalized as a stand-stand-alone, cloud-based platform for the use of other container terminals.